WAGES represent WATER, AIR, GAS, ELECTRICAL, and SPACE.

AIR poses significant challenges in heater installations, often leading to issues like excessive soot buildup and condensation. Indoor pump rooms typically lack sufficient combustion air, especially for Low NOx heaters with blowers requiring air assistance for combustion. Even outdoor pump rooms often lack proper combustion air placement, as mandated 12” off the floor.

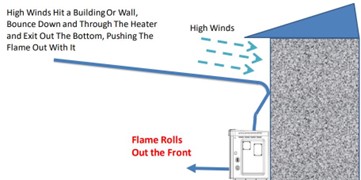

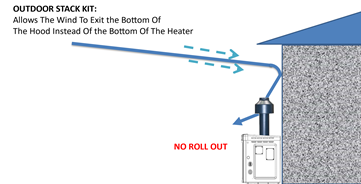

Now, let’s address “outdoor heaters.” A true outdoor heater stands alone without any surrounding structures like walls, enclosures, or roofs. However, heaters placed outside of elements are often mistakenly considered outdoor installations. Many instances involve high pony walls and rooftops posing challenges for outdoor heaters. We’ll discuss combustion air, exhaust venting, and when to implement outdoor stacks, as well as suitable exhaust venting options. If a heater is genuinely “outdoors” but positioned against a wind-facing wall, an outdoor stack is likely necessary to prevent roll-out issues. Here’s an example image for reference:

Here are some pictures highlighting a few issues. Please Note: We do not know who installed these jobs, however these images make for a good learning tool for all installers.

Situation: Heater positioned near the corner of an “outdoor” pony wall.

Issue #1: The Low NOx air intake is too close to the wall/corner, hindering sufficient airflow into the heater. Proper combustion air openings, positioned 12 inches from the floor, are required for adequate airflow.

Issue #2: The outdoor stackless top is unsuitable for use if the unit is less than 6 feet from the corner (as previously described). Depending on the wall’s height, the D-11 outdoor draft hood may be viable (painted and rain cap not required), provided it can clear the pony wall. If not, an alternative venting option must be explored. If uncertain, it’s advisable to consult the Raypak applications department for guidance, reachable via email at: Commercialapplication@rheem.com.

Situation: Four heaters installed within an “outdoor enclosure” featuring pony walls extending 4 feet above the height of the heaters.

Issues: Specific concerns regarding power vents and exhaust are outlined below. However, it’s crucial to note that despite the room having a roof, the venting must extend above the pony walls for proper ventilation.

It’s essential to remember that the wind doesn’t behave like a roller coaster. It doesn’t blow directly into the room, takes a 90-degree angle downward to lift exhaust fumes out. Proper venting is necessary to carry away the fumes up and over the wall, preventing excessive soot buildup on the heat exchanger. In this scenario, the exhaust fumes are dispersing at shoulder height, typically where someone would be standing in a pump room, posing a risk of inhaling these fumes. While the outdoor enclosure includes a gate for entrance, incorporating additional air intake at the bottom of the pony walls would be advantageous.

Type of venting material:

From the Manual:

The 4″ collar atop the D-2 Power Vent requires a gasket-to-gasket flue adapter in order to properly connect to your selected brand of 4″ Category III flue pipe. Contact your HVAC distributor.

Comments:

Cat III venting must be installed on the OUTSIDE of the collar.

This will prevent flue gases from escaping. See page 10 of the D2 power vent manual.

Top of D2 Power Vent:

From the Manual:

For through-the-wall (sidewall) installations, the screened elbow supplied with the D-2 Power Vent must be used as the flue termination. Install the elbow so that the screened end faces directly downwards and is at least 12″ (305 cm) from the wall. Alternate sidewall vent terminations shall not be accepted; see the National Fuel Gas code, paragraph 12.4.3.1

Comments:

Kindly be aware that according to page 10 of the D2 power vent manual, the screened portion provided with the power vent is intended solely for sideways venting termination. It should be oriented downward with the 90-degree elbow included and should never face upward. For all vertical exhaust pipes, a field-provided termination cap should be utilized.

Incorrect/damaged venting on indoor installation:

Situation: There is a hole in the exhaust vent.

Issue: Anyone entering the pump room risks inhaling exhaust fumes, including potentially deadly carbon monoxide. Carbon monoxide is colorless, odorless, and can be fatal if breathed in. If such a problem is observed in a pump room, immediate adjustment is imperative.

Frequently Asked Questions:

1) How many amps does the D2 power vent draw?

Answer: The D2 power vent draws 2 amps when operating on 115VAC power and 1 amp when operating on 240VAC power.

2) When can/should you use an outdoor stack if there is a pony wall?

Answer: An outdoor stack should be used to ensure exhaust fumes clear over the pony wall and are carried away. If there is a roof structure, there must be 3 FEET of clearance above the stack before the roof. If there is insufficient room, venting should be run through the roof, ensuring clearance of TWO FEET with a rain cap. Alternatively, a D2 power vent with 4” category III venting can be used to go over the pony wall.

3) Do I still need combustion air vents 12” off the floor if the heater is “outdoors” surrounded by pony walls?

Answer: Yes, combustion air vents are still necessary. Wind does not curve and reach down to the floor to be sucked in by the heater. Therefore, airflow is required. Even on indoor heaters, additional air venting is required per NFGC, even when direct vented.

4) Can I install a new heater the same way the old heater was and re-use the old venting?

Answer: Yes, provided the installation was done correctly, and there is no damage to the venting. Inspection and verification are essential. As the new installer, your customer expects you to perform the installation correctly and to code. Do not assume the previous installation was correct, as incorrect installations are more common than correct ones.