As variable-speed pumps (VSPs) and high-efficiency heaters have become standard in pool system design, the critical practice of external bypass valve installation and tuning has fallen by the wayside. Yet, as heater failures and efficiency issues continue to surface, it’s clear that this once-routine technique is more relevant than ever.

Pool and spa heaters perform most efficiently when the rate of heat transfer (in BTUs) is matched appropriately to the volume and velocity of water passing through the heat exchanger (HX). A lower flow rate allows more heat to be absorbed by each pound of water, increasing the temperature rise—or ΔT—between the inlet and outlet.

This highlights a key principle: lower flow equals greater temperature rise. Conversely, higher flow dilutes BTU impact, producing a smaller ΔT.

Today’s variable-speed pumps are capable of flow rates far beyond traditional system design expectations—even at mid-range speeds (e.g., 2700 RPM, 80–100 GPM). While manufacturers rate heaters to handle flows between 40–100 GPM, most heat exchangers only route a portion of that volume internally.

When flow rates exceed HX design limits, several issues arise:

-

- Velocity erosion: Stripping of copper from internal HX surfaces

- Thermal warping: Caused by hot spots and inconsistent flow distribution

- High-limit trips: Triggered by elevated HX temperatures

- ΔT deviation faults: Too high indicates low flow; too low indicates excessive flow

These risks are amplified when systems lack an external bypass valve to regulate hydraulic pressure and velocity through the heater.

Built-in bypass mechanisms inside heaters use spring-loaded valves to redirect a portion of water away from the heat exchanger, but these are insufficient in systems where variable-speed pumps dominate or where hydraulic restrictions create unintended flow surges or lower flow rates with higher velocities, similar to installing a high pressure nozzle on a garden hose.

How does this happen? All the plumbing repairs over the years, additional equipment installed such as Salt Systems, Ozonators and UV systems. This doesn’t include the additional hydraulic restrictions and surges created when inside pipe fittings are used,, 3-way valves and, chemical feeders are installed, additional 90-degree elbows, 45’s etc. that were never calculated in the original pipe sizing for the system hydraulics originally. The unintended consequences of all this additional equipment on 2” plumbing is additional turbulence, velocity and increased flow rates through the heat exchanger.

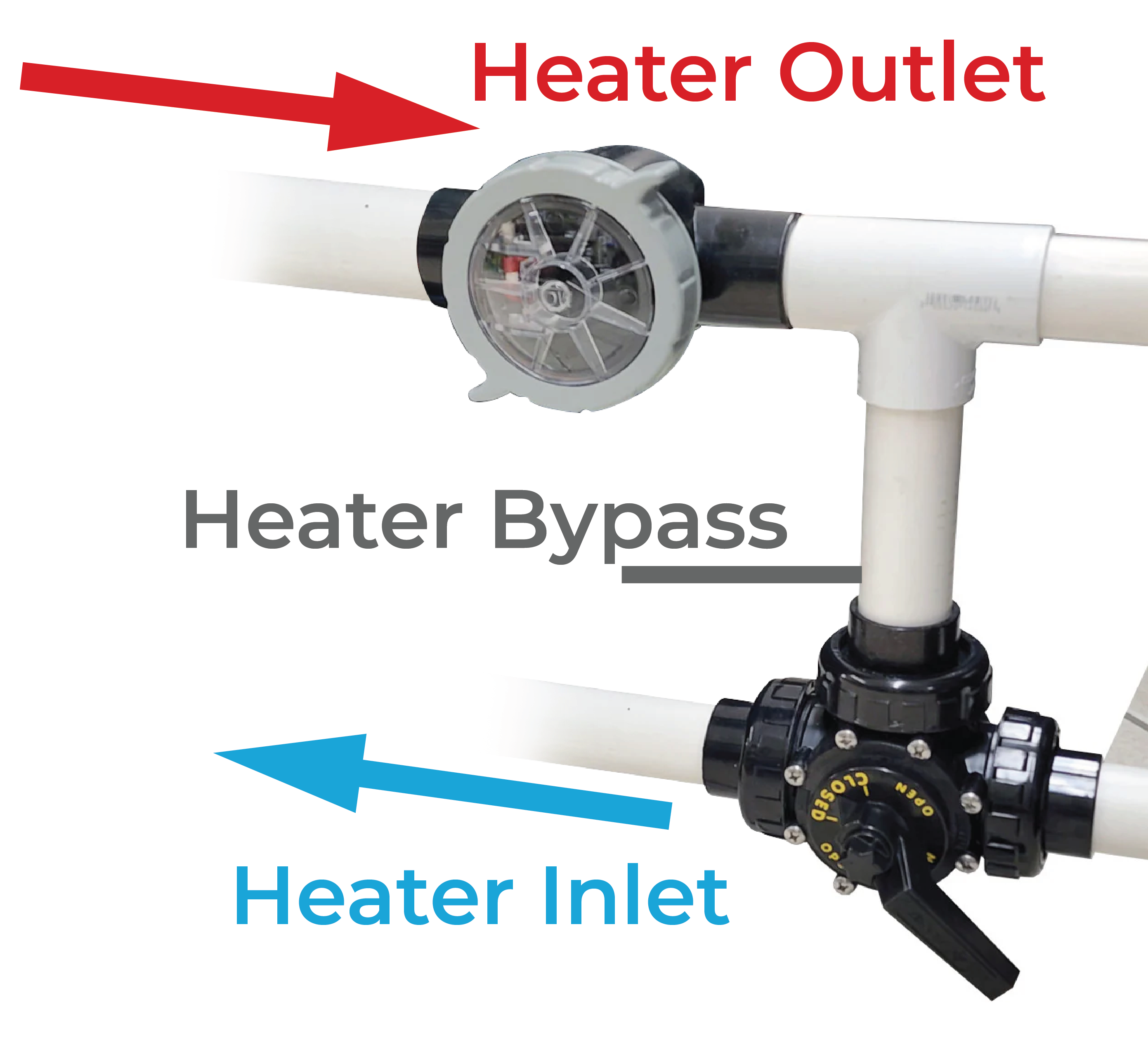

An external bypass valve—typically a loop with a ball valve—allows field technicians to adjust how much water bypasses the heater entirely.

Another versatile option is a bypass created with a 3-way valve and a check valve. This array helps to control the flow thru the heater, avoiding the water back flow due to the check valve function. This array allows as well to fully isolate the heater for periodic maintenance.

Please note that if you close this valve long term, warranty is void if chemical damage occurs as the heater should be drained.

When tuned correctly (often with the aid of a flow meter), the system can maintain the ideal 50–55 GPM through the heater, which in turn:

-

-

- Maximizes heat transfer (ΔT optimization)

- Reduces wear and erosion

- Prevents condensation-related corrosion

- Avoids temperature rise or high-limit faults

-

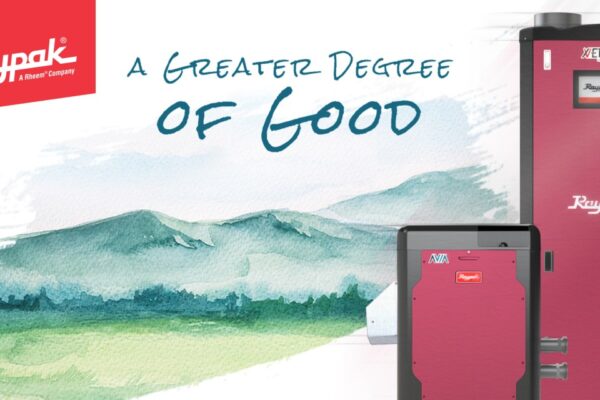

The Raypak AVIA gas heater has been designed to operate at the intersection of modern flow management and advanced control logic. It includes features that align perfectly with best practices for external bypass valve integration:

-

-

- Inlet and outlet temperature sensors provide real-time ΔT calculations

- Four-pass heat exchanger design ensures extended contact time and optimized energy transfer

- Flow fault monitoring ensures system safety and provides diagnostic data. These faults are recorded in the Service menu:

- Low Flow Fault: Triggered if ΔT exceeds 63°F (Model 264) or 64°F (Model 404)

- High Flow Fault: Triggered if ΔT falls below 31°F (Model 264) or 35°F (Model 404)

- Hydraulic thresholds for HX flow are tightly defined:

- Model 264: 7–14 GPM

- Model 404: 10–19 GPM

- AVIA Service menu provides real-time calculation of the flow thru the HX. This menu can be used to fine-tune the flow and optimize the operation of the heater.

-

AVIA’s built-in intelligence ensures system safety and efficiency, but it relies on proper hydraulic conditions—and that’s where the external bypass valve becomes critical. It allows installers to fine-tune the flow, so that as hydraulics and the necessary pump speeds change from jobsite to jobsite, individually, each customer’s maximum heating efficiency can be not only achieved but maintained at all flow rates. This allows the heater’s internal monitoring systems to function properly, and the unit avoids damaging thermal or mechanical stress.

The consequences of flow mismanagement are well documented:

-

-

- Too little flow causes HX overheating, warping, high-limit trips, and scaling

- Too much flow increases the chance of internal condensation

- When HX outlet temperatures drop below 100°F, acidic condensation (exhaust gas pH 3.5-5.5) can form

- This leads to corrosion and premature heater failure

-

Maintaining outlet temperatures above 100°F (to prevent condensation) and below 135°F (to prevent scale) is critical. External bypass valves give technicians the fine control needed to keep systems in that safe thermal window.

Even with modern heater diagnostics, traditional tools remain valuable:

-

- Pete’s Plug with thermometer: Provides accurate outlet temperature readings

- Flow meters: Installed in the bypass loop to fine-tune bypass valve adjustments

- Manual ball valves: Enable dynamic flow redirection around the heater

These analog methods remain effective for commissioning and troubleshooting, especially in systems where digital monitoring may not be available or is temporarily offline.

In today’s pool and spa systems, external bypass valves are not just helpful—they’re essential. With powerful variable-speed pumps and precise heater diagnostics like those in the Raypak AVIA, it’s more important than ever to control flow dynamically.

By integrating and properly tuning an external bypass valve, professionals can:

-

- Ensure correct flow through the heat exchanger

- Extend heater life

- Prevent common failure modes

- Maximize heating efficiency and temperature rise

It’s time to bring back the long lost art of bypass valve installation—because even the most advanced heater is only as good as the water flowing through it.